Page 58 - royal-times-11-12

P. 58

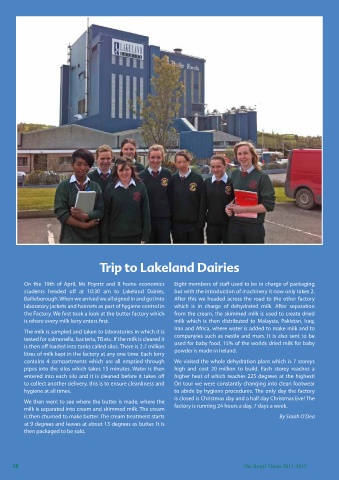

Trip to Lakeland Dairies

On the 19th of April, Ms Poyntz and 8 home economics Eight members of staff used to be in charge of packaging

students headed off at 10:30 am to Lakeland Dairies, but with the introduction of machinery it now only takes 2.

Bailieborough. When we arrived we all signed in and got into After this we headed across the road to the other factory

laboratory jackets and hairnets as part of hygiene control in which is in charge of dehydrated milk. After separation

the Factory. We first took a look at the butter factory which from the cream, the skimmed milk is used to create dried

is where every milk lorry enters first. milk which is then distributed to Malaysia, Pakistan, Iraq,

Iran and Africa, where water is added to make milk and to

The milk is sampled and taken to laboratories in which it is

tested for salmonella, bacteria, TB etc. If the milk is cleared it companyies such as nestle and mars. It is also sent to be

is then off loaded into tanks called silos. There is 2.7 million used for baby food, 15% of the worlds dried milk for baby

litres of milk kept in the factory at any one time. Each lorry powder is made in Ireland.

contains 4 compartments which are all emptied through We visited the whole dehydration plant which is 7 storeys

pipes into the silos which takes 15 minutes. Water is then high and cost 20 million to build. Each storey reaches a

entered into each silo and it is cleaned before it takes off higher heat of which reaches 225 degrees at the highest!

to collect another delivery, this is to ensure cleanliness and On tour we were constantly changing into clean footwear

hygiene at all times. to abide by hygiene procedures. The only day the factory

is closed is Christmas day and a half day Christmas Eve! The

We then went to see where the butter is made, where the

milk is separated into cream and skimmed milk. The cream factory is running 24 hours a day, 7 days a week.

is then churned to make butter. The cream treatment starts By Sarah O’Dea

at 9 degrees and leaves at about 13 degrees as butter. It is

then packaged to be sold.

58 The Royal Times 2011-2012